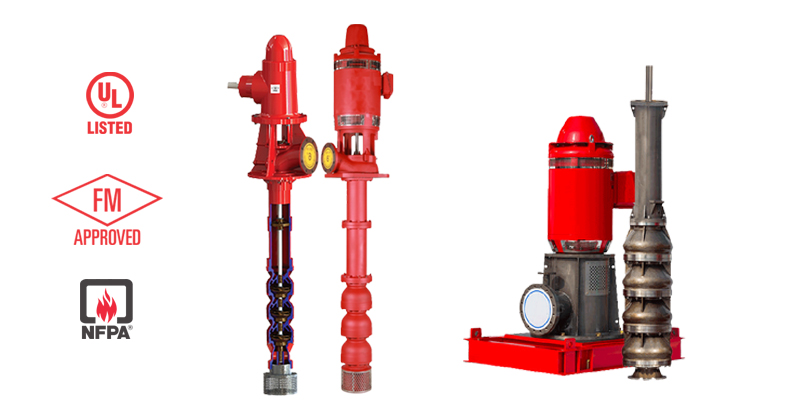

Split Casing Fire Fighting Pumps

Technical data

- Flow, Q:max. 2500 m3/h

- Head, H:max. 148 m

- Liquid temp: -12°C to + 100°C

Applications

The pumps are suitable for liquid transfer in

- Fire fighting systems

- District heating plants

- Water supply systems

- Air-conditioning systems

- Cooling systems

- Irrigation systems

- Other industrial systems.

Features and benefits

- Flange dimensions according to BS 4504/DIN 2501 standards

- Robust design

- Wide range

- Standard motor

- Adaptable to any application and performance

- DIN 24960 shaft seal.

Standard material

- Casing : Cast iron / Ductile Cast iron / Stainless steel

- Shaft : C-steel / Cr-steel

- Impeller : Castiron / Brass / Bronze or stainless steel

Description

- The casing is axially split, which permits removal of the complete rotor without moving either piping or motor. Pumps generating high heads have double volutes to reduce radial forces. Replaceable wear ring protect the casing at the impeller running clearances.

- Flange dri l led to ISO, DIN, BS or ANSI.

- The close double suction impel ler gives practically zero axial forces. Each impeller is statically and dynamically balanced according to ISO1940.

- Vertical or horizontal, soft packing or mechanical seal, grease or oil lubrication bearing on request.

Options

- Various types of shaft seal depending on liquid, temperature and pressure

- Stuffing box

- Cast iron, bronze or stainless steel impeller and wear rings.